Good Morning! I hope you are doing well. So, I have been getting so many emails for you all about buying a Singer 301 on Ebay. Well, I say go for it! See, look at me I won 2. One was a mistake, but don't tell her that. Not that she is not fabulous, I just didn't mean to buy 2. I rarely win anything on Ebay, so I bid on 2 different machines assuming I wouldn't win either. More the fool I, right? Well, I am just happy they were both under $50. I am pretty sure if I drag another machine in the house my husband will have me go to counseling. I do love to teach quilting on these older machines though. They are so simple and do everything you want them to each time. Well, they will after a bit of love from you, their new mom. So, let's get to it, shall we?

Here are your supplies. Pretend I have an old toothbrush and some Q-tips in that shot. And make sure you aren't wearing anything you don't mind getting a bit dirty.

These items are really important to your old gear driven machines. Oil and Lubricant. They are not the same and you will need both.

Lets begin at the bottom. Take off the drip pan bottom by unscrewing the thumbscrew in the center. It should be easy. It may be nasty in there so prepare yourself. One of mine was...that other was not that bad. Wipe off the dust and grime with your cloth. You can also use your canned air. Turn the hand wheel over on the side of the machine and notice all the moving parts. Oil all of them. If you have a manual you will see that it says to do this on page 28.

This is the gear on the bottom of the machine. There are 2 places you will need to add lubricant on the bottom. The Gears and the Motor. Give the gears a dab of lube. A dab of lube on each gear, then turn the hand wheel to spread it around. I like doing this.

See, just a bit. Now if there was lots of black goop all over the gears, take your Q-tip and gently remove it before adding the new lube. Try not to leave all the cotton from the Q-tip behind in the gears.

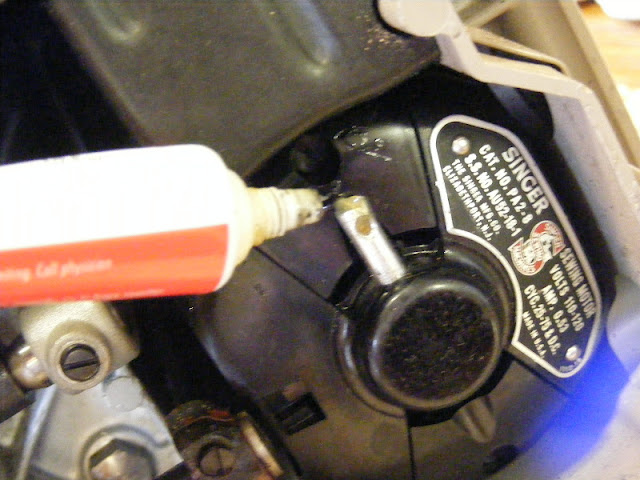

You will also need to give a dab of lube to this little zert on the motor. These are old motors and need to be manually lubricated.

Oh I wanted to show you this little melted foot. I will need 4 new ones for each machine. They are cheap, so that is a nothing fix, but it is important otherwise my machine will be unsteady when I sew. I will have a source list down at the end of this post.

This is what the foot should look like.

Now, this is very important. This is the bobbin area. Do you see that finger piece at the top of the bobbin area? It has got to be in the notch made for it in the bottom of the throat plate. If it is not in position the machine will sew terribly. You will be sad and think that you bought a lemon. ALL the old Singers I have bought over the last 2 years were not in the correct position, so I guess the sellers thought they were broken. Isn't that funny? I think it is. You just have to be very very very careful after you take the throat plate off and put it back on. It is one of the most simple fix. The other simple fix is making sure the needle is in correctly.

So, you will need to take off the throat plate and clean out all the lint beneath the feed dogs. Just be careful when putting the throat plate back on. Make sure the "position finger" is nestled in the notch of the throat plate.

Oil the bobbin case

Now to the top part. Take out the 2 screws on the top of the machine and flip open the door on the side of the sewing machine.

Once again, turn the hand wheel and oil everything that moves. There is great deal of up-down movement in this area. So oil the parts.

This part of my short bed machine was seized up. The presser bar lifter did not actually lift or lower the presser foot. I was sad. I made my husband come give me his opinion. He is handy. He told me that I needed to bang on it. What? How about we bang on it and oil it at the same time? Worked like a charm. It was quite stuck, but with some oil and some manipulation it worked fine. Keep that in mind when you are tending to your machine.

Clean off the goop from the gears.

Add a dab of Lubricant to this set of gears and...

add some to this set too. Now turn the hand wheel. Go ahead and oil all the moving parts (but no the gears. The gears only get lubricant). Oil the insertion points of the pieces. Turn that hand wheel (towards you - not away)

This is another part you will need to oil. The bobbin winder. It needs oil too! Mom, you oil this spot on your featherweight and it will wind like a champ. I know it looks a bit different on the featherweight, but it needs oil.

Put the cover back on the top, replace all the screws and shut the little door on the side and you are ready to sew! Hot dog. I recommend you stitch with some scraps so they can absorb the oil that is sure to be around. Since you added lubricant to the motor it needs to be run for a bit, so the motor can suck the lubricant inside itself.

Now, you do not need to be this through with your oiling each time you use your machine. There are lots of holes all along the tops of the machine and on the base. Give each hole a drop of oil, turn the hand wheel a couple times and you are good to go! I don't oil mine each time I use them either. I oil about every 3rd time. I do make my students oil when they bring them out of the boxes because it is a good habit to get into.

So, you may wonder why I know this stuff? Well, when my very first little featherweight arrived from my uncle, I took a class at a local lady's home. She had a way worse addiction to sewing machines than I do. She had like 9 featherweights and 13 of the 301s. But....she knew everything about the sewing machines. She taught me so much.

You will need a good source or 2 for your parts

and

This is a neat one too- Sew Classic Blog

OK, I am off to so paint with Sharon! Have a great day, and PLEASE let me know if you have any questions. These are great old machines and I want to help you get yours up and running.

10 comments:

Great post very imformative. Thanks!

oh my gosh tia! you are such a font of knowledge!. that lady must have been fabulous to know. i will be good to my girl once she arrives and give her a good oil and lubing. i am always so afraid of doing these kinds of things, but this really is stuff everyone that has a machine should know (especially if you are addicted to old machines). thank you so much for doing this tutorial of sorts for keeping them in tip top shape. and i do think its sad and funny that those ladies probably sold off their machines for something so small, but if you dont know??!!

i will upload a pic of befores and afters

Do you happen to know anything about Necchi sewing machines? I bought one about a year ago at my local Goodwill and have been meaning to take it in for a good cleaning, but haven't gotten around to it yet.

And then I read down a few posts and see that you have a Necchi too:-) Mine is a different model than yours, it has lots of fancy embroidery stitch plate things that kinda scare me a bit!

Great tutorial on servicing this machine. Thanks for taking the time to put this together and share your knowledge.

Tia you always amaze me with your wealth of information. I love your work and enjoy reading your blog I would like to award you the Liebster Blog Award. The Liebster Blog award is presented to blogs that the presenter believes should be recognized. It is given to "small blogs" - those with fewer than 200 followers. Check out my blog for more details. Congratulations! :)

Based on your advice, I was looking for a 301, but was given a 201. Are the instructions basically the same? My husband is printing off a manual, but I like your instructions and photos much better :)

Thanks!

Awesome post! Thanks so much for sharing all this with us! I love when I look on google for tips and find a blogging/flickr friend has written up a post that's just what I was looking for!

I'm lucky enough that my landlord just dropped one of these off for me - it once belonged to a friend of theirs who no longer wants it. What a find!!

Thank you so much for the information. I have been hunting all over for more details about how to grease the gears of my Singer 221 (Featherweight) than what my manual had, and I finally found the answers to my questions here! Even better, reading your warning about importance of getting the bobbin casing position finger in the correct spot after removing the throat plate (for cleaning around the feed dogs), I realized that I needed to fix that! I am sure you saved me from a great deal of aggravation from that mistake. Thanks so much! Happy sewing - Cindy.

Well at least when you won both machines, they weren't exactly the same. I see you got a long bed and a short bed machine. A pretty good post, but I think you need to cover the stop motion screw and how to clean the outside of the machines as well as shining the medal pieces of the machine. Because sometimes they can be very dry and dirty. And if you do re-vise your tutorial to add them don't forget to put in the picture, to take a sharpie and mark on the stop motion screw on each side and on the washer of just one end so you will know how it goes back on. And I also shine my medals like the presser foot lifter, needle bar, clamp, tension disc and just anything shiny. But I sure am glad to see that there are other ladies out there that love these old machines as good as I do. I have 19 of these lovely gals of all makes and models, and still don't have all of the ones on my bucket list. But at least we are saving them from ending up in the scrap pile. Good luck with yours.

Post a Comment